An Opinion

On the maintenance of EPSON SureColor P6000, P7000, P8000, & P9000 printers. And Stylus Pro 7890, 7900, 9890, and 9900 for that matter!

This printer family replaced the Stylus Photo Pro 7890, 7900, 9890 and 9900 printers and unfortunately inherited much of the same problems as they share the same print head. There is a tendency for this print head, possibly due to the powerful clean maintenance procedures, for the ink channels to delaminate when power cleaning is used when air (or some form of clog) is present. These powerful cleanings apply stimulus to the jets and in our opinion, this stimulus should not be employed other than in routine maintenance when a few missing nozzles are presented on the nozzle check.

EPSON utilizes an auto-cleaning feature that many users turn off to save ink costs. It is probably there for a reason of remedy. What Canon does in many of their printers is to agitate their own ink supply continuously to avoid pigment agglomerations. It is also the reason why a color Canon printer cannot be converted to Piezography – as the ink is withdrawn from the ink carts into a small chamber and then re-expressed with force into the carts. This ink reserve will contaminate Piezography inks with color and there is no known way to empty the ink reserves other than dismantling and replacement of expensive components. But, the idea is ingenious in terms of printer self-maintenance. We liked the way that the older generation of EPSON printers swayed back and forth while printing. If it was not an intentional design feature it sure helped in ink agitation. The old 7000/7500/9000/9500/7600/9600 printers seem to last forever before needing a new print head and they swayed back and forth.

Why nozzles become missing with OEM inks is a subject of debate. Either agglomerations of pigment or trapped air are the most likely. EPSON licenses its print heads to professional equipment builders such as Mimaki which does not use the EPSON method of using air filled dampers. Instead, they use a degassed ink. The ink lines feed directly to the print head. Absolutely no air is present in their ink delivery system. We know this because we formulated degassed private label inks directly for Mimaki and they explained the importance of degassed ink in their specifications. When ions of gas become present a nozzle can mis-fire resulting in a missing line on the nozzle check. A tiny agglomeration of pigment trapped in the ink channel or in the jet can produce the same symptom. A dirty ink damper which not only contains air but also a small mesh filter can also produce the same symptom.

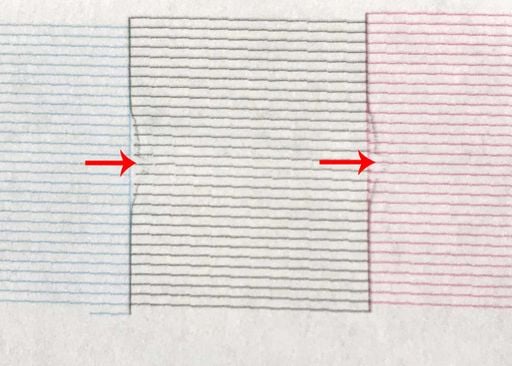

According to our customers, using repeated power clean operations during this type of event (be it air or trapped pigment clusters) can eventually result in a swath of missing jets during the nozzle check test. And it is at this point we believe it very difficult if not impossible to recover those channels that exhibit these swaths which we attribute to some form of “delamination”. This is not to say that some customers through incredible patience have recovered a print head previously in this delaminated condition. It is rare however - either due to the patience and time required in the use of PiezoFlush over a very long period or the print head itself.

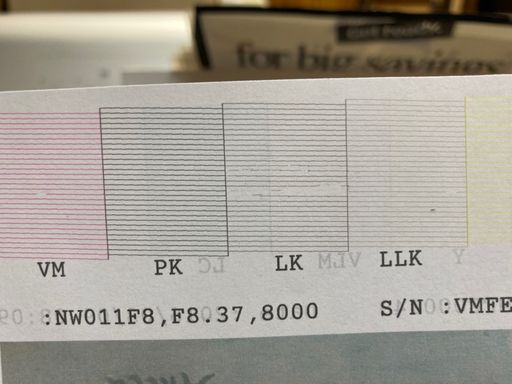

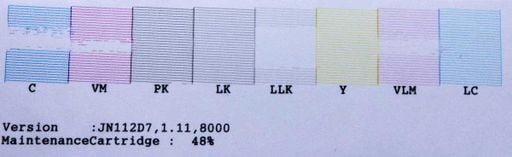

These are the beginnings of a delamination

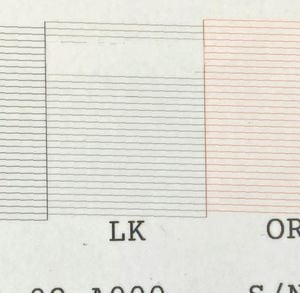

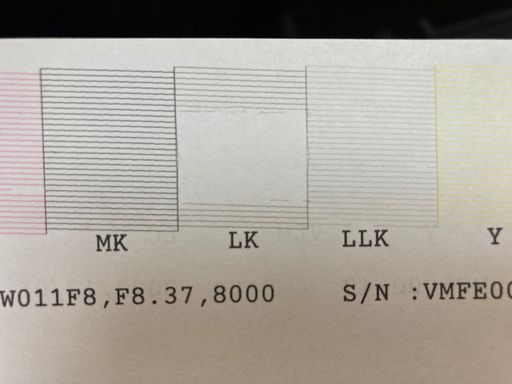

And these are delaminations

While we do not de-gas our ink formulations for use in EPSON printers (only because EPSON printers use air filled ink dampers), we do filter the inks extensively and in the case of Piezography inks use extremely small pigment particles to prevent agglomerations. So, we have an extremely good track record as it regards clogging and we are able to give a much longer print use life to our inks than EPSON own six months. In fact, most of our customers will use their original ink purchase for more than a year and sometimes several years. This is due to the nature of photo and fine art printing. Some of our commercial printers will use the same amount of ink in only a month.

Because this appears to be the last generation of printer model that EPSON will sell into the USA market that can be used with your choice of 3rd party inks, our opinion is that you should, more than ever, employ preventative maintenance procedures.

Firstly, when a nozzle check shows one or more missing lines that are not recovered in 2-3 regular cleanings exercise patience. It may be an ion of air that will dissipate back into the damper within 24 hours. So give it a rest for a day in between attempts. If you are in a hurry due to job constraints and you must clear this situation using powerful cleaning no more than once in an hour. If that does not remedy it within three attempts you can employ an INIT FILL which will apply only strong suction and no electrical stimulus to the print head.

You can help your own situation as a preventative routine to remove your ink carts every two weeks and gently shake them to re-suspend any pigment particles that are either settling or forming agglomerations.

EPSON did not necessarily design their printers for occasional use. Their professional models are capable of being used over three shifts and usually without fail! It speaks highly of the quality of these printers. But like an automobile that is taken out on occasion for a short drive and allowed to sit for long periods of time, a printer treated the same way will begin exhibiting signs of disuse. Ink pigment is heavy and it settles. When it does, the fluid components that are thinner will print and you will see this as “changes” in images that are familiar to you when you reprint or unexpected results compared to what you are used to. Pigment settling itself besides lining the bottom of ink carts, ink lines, and other critical components restricts what are already tiny operating areas for the ink to travel in and through.

We do NOT believe that you should allow pigment ink to remain in a printer that is going to be unused for more than 6-8 weeks regardless of it employing auto cleaning every two hours. These are large format printers with as much as 30ml of ink between the ink cart and print head. That is ink that should be moved out and refreshed at a normal pace. We recommend that you use a PiezoFlush kit to replace the ink carts and run the INIT FILL to flush out the pigment ink and replace with PiezoFlush as a storage fluid. If an emergency happens and you can not do this type of preventative maintenance – then when you return, remove the carts and shake them gently and then run the INIT FILL to push out the stale ink.

Your cleaning box contains a number of user replaceable parts such as the wiper blades which tend to cup over time. The flush box itself begins to gum up and can be cleaned with a fluid like PiezoFlush so that it better drains. This gunk that forms can cause foam which an old wiper blade can not completely remove and when you see drops of ink on your prints you have gone past the point of preventative maintenance to these areas. It may be time to replace the clean box and capping stations if you can not get them to the pristine condition they once were. We do provide a PiezoFlush large format preventative maintenance cleaning kit which we believe you should use every six months.

Finally – because these printers are valuable to those who depend upon them for use with Piezography inks, you should communicate to the community before discarding one because it has one or few bad ink channels. A P7000 or P9000 can be used as a full Piezography system with two missing channels, and can be used as a Piezography digital negative system with as many as five missing channels, and can be used as a Piezography direct to plate printer with as many as seven or even nine missing ink channels. If you are a color printer you can always purchase a new color printer – but not so with Piezography B&W printing. It is unique as a highest standards medium in being able to use a printer with a bad head. We produce a software for remapping our media profiles. Unfortunately this does not work for color ink customers who require all print channels present.

NOW SOME IMPORTANT INFORMATION CONCERNING CHIPS and the SureColor P6000, P7000, P8000 and P9000 printers that were manufactured for sale in North America, South America and Europe.

These printers have a main board installed (one of the most expensive parts) that records the serial number of each cartridge chip that has been inserted into the printer. There is no way to disable this or turn it off. What the function does is determine if the chip serial# that has been inserted was inserted previously and had a lower % of ink remaining at a previous time than it does now. If it did the printer will not operate. What this does is prevent chip resetting which in turn prevents the use of 3rd party carts. There were 10 serial numbers per ink channel created prior to the collapse of the availability of semi-conductor chips. It is highly unlikely that any more serial numbers will be produced because of the ongoing worldwide shortage of semi-conductor chips.

Therefore, if you purchase a SureColor P6000, P7000, P8000 or P9000 printer of which you do not know its entire history of use with 3rd party inks you may find that you are unable to use it because it has already been used with some or all of the available 3rd party chip serial numbers. Because the chips we sell are not returnable – it is imperative that you discover this prior to purchasing chips or you will necessarily be forced to use this printer only with OEM inks.

The only remedy to this situation is the purchase of and installation of a main printer board from the China region. Printers sold in China must be able to be used with choice of inks. The printer main board does not track chip serial numbers in the same way that a USA printer does and a printer outfitted with a China region main board can be used with a simple chip resetter. The cost of a system is about $1,800 and you are responsible for the installation of it including any harm you might do removing and replacing sensitive ribbon cables (parts which are available but remain your responsibility.)

Therefore it is better to purchase a used printer for 3rd party ink usage that has not previously been used for 3rd party ink usage unless the owner can provide you with exactly what chip series have been used in each color position.